JUNE 18, 2008

VANCOUVER, BRITISH COLUMBIA – June 18, 2008 – Silvercorp Metals Inc. (“Silvercorp” or the “Company”) is pleased to report successful exploration results at the newly acquired TLP Mine at the Ying Silver Camp, Henan Province, China.

The TLP vein system is composed of 10 veins, 6 of which are roughly parallel and are stacked en-echelon veins with a strike length of up to 3 km. Historical exploration on the T1, T2, T3, T4, T5, and T6 veins has resulted in historical mineral resources, calculated between 1,100 metre and 700 metre elevations for these veins, of 3,688,343 tonnes grading 292 grams per tonne (g/t) silver (Ag) and 3.30% lead (Pb) (Chinese Government Standard Class C+D). As a non – NI 43-101 compliant resource calculation, and as mining of the resource by the prior operator has occurred, the resource cannot be relied upon.

The current goals for TLP exploration program are: (1) to evaluate the remaining quantity of the historical resources of the existing veins after the previous operators operations; (2) to define the strike and dipping extension of the existing veins; and, (3) to discover new veins. The results of the exploration program may form the basis, of a resource estimate in accordance with NI 43-101.

From March to May 2008, Silvercorp’s field crew:

– surveyed and mapped over 45,000 metres (m) of old tunnels and stopes,

– took 3,300 channel samples,

– developed 2,645m of new tunnels, and

– completed 3,309m of diamond drilling (four surface holes and one underground hole).

All five drill holes intercepted the apparent silver (Ag) and lead (Pb) mineralization with assay results pending for 4 holes.

The program so far has confirmed a substantial amount of historical resources remaining in-situ, and drill holes have extended the main veins, T2,T3,T4 and T5 by 800m along strike and by 200m down dip to about 500m elevation, below the 700m elevation historical mining boundary. In addition, two new high grade Ag-Pb veins (T14 and T20) have been discovered in tunnel.

Significant results from tunnels and drill holes:

> 2.2m true width grading 1,118 g/t or (35.96 oz per tonne-oz/t) Ag, 24.33% Pb, 0.27% Zn and 2.10 g/t Au (gold) on the 800m elevation T2 vein.

> 0.70m true width grading 1,142 g/t or (36.73 oz/t) Ag, 4.09% Pb, 038% Zn and 0.76 g/t Au on the 725m elevation T3 vein.

> 0.40m true width grading 1,570 g/t or (50.47 oz/t ) Ag, 4.75% Pb 0.18% Zn and 0.92 g/t Au on the 800m elevation T4 vein.

> 0.78m true width grading 342 g/t or (10.97 oz/t) Ag, 17.21 % Pb and 0.21 %Zn on the 725m elevation T5 vein.

> 0.40m true width grading 1,914 g/t or (61.53 oz/t) Ag, 12.28% Pb and 0.87% Zn on the 960m elevation T14 vein.

> 0.30 m true width grading 1,764 g/t or (56.71 oz/t) Ag, 18.64% Pb and 3.03% Zn on the 780m elevation T20 vein.

> 0.60 m true width grading 208 (g/t) or 6.68 (oz/t) silver Ag, 4.87% lead (Pb) and 0.79 % (Zn) on the 930m elevation T1 vein.

> Surface drill hole ZK6501 intersected 0.40 m (core length) on the T3 vein at the 662m elevation grading 111 g/t or (3.56 oz/t) Ag and10.28% Pb and 0.02% Zn.

Newly Discovered Veins

T14 Vein

The vein does not show on the surface and was only intersected by tunneling. The vein strikes north-northwesterly and dips 80 degrees to the east. The T14 vein has been explored through main access tunnels PD890, PD930 and PD960 at 890m, 930m, and 960m elevations, respectively. A total of 210m drifting has been completed on the vein. To date T14 vein mineralization has been traced for 100m along strike on the 890m level.

T20 Vein

The T20 vein is not mapped out on the surface and was discovered by drifting on 780m elevation through main access tunnel PD780. The vein extends nearly north-south and dips 84 degrees to the east. To date, high grade mineralization of the T20 vein has been traced over 120m. Vein T20 is typified by well defined silver rich, massive galena and sphalerite. Zinc mineralization is notably higher than other veins at the TLP mine. The vein ranges 0.10 to 0.75 m in true width.

The T14 and T20 shows a developing trend of vein sets which are striking approximately north-south, compared to the 035 degree strike of veins T1 to T6, which represents a new vein orientation not previously recognized.

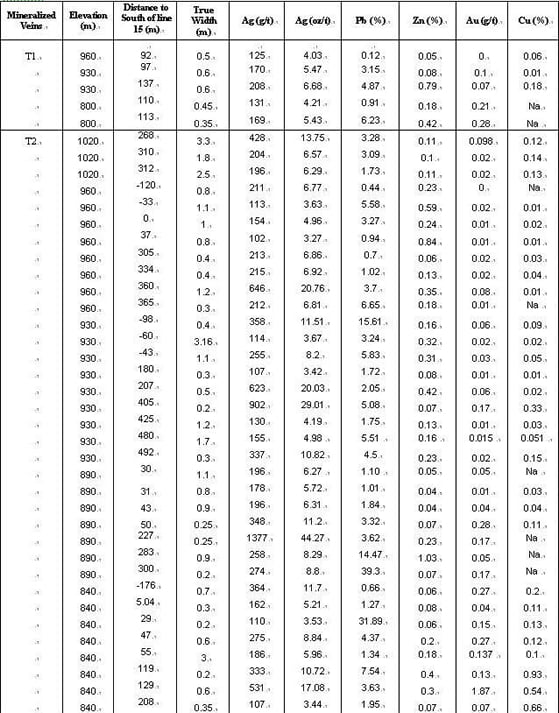

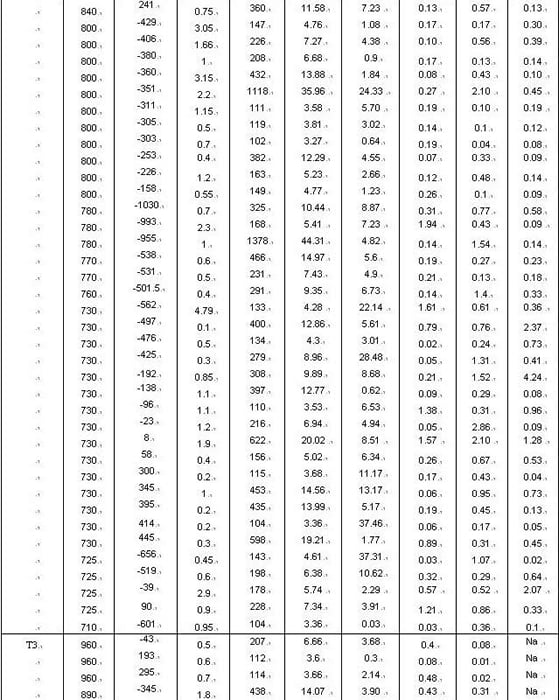

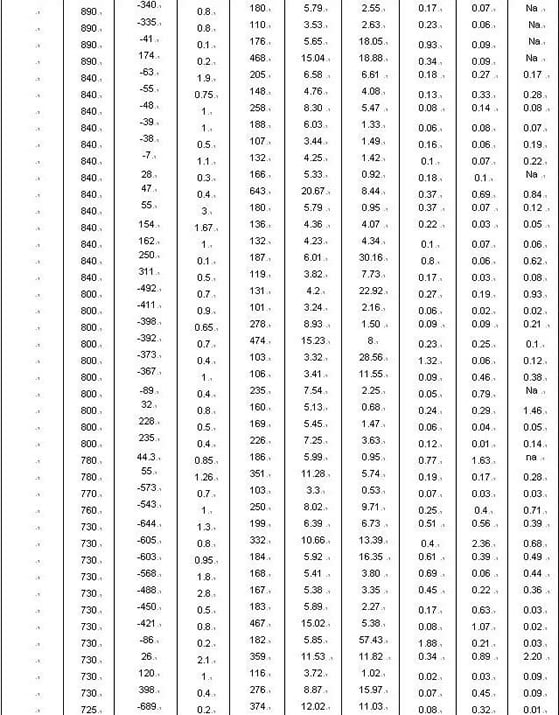

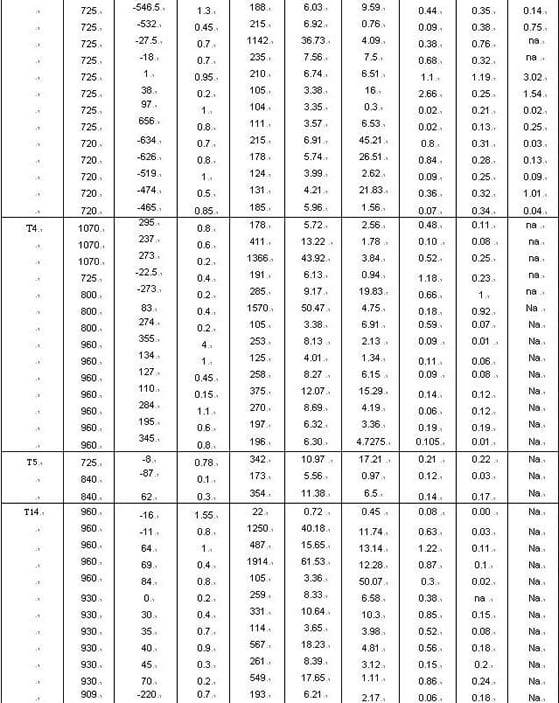

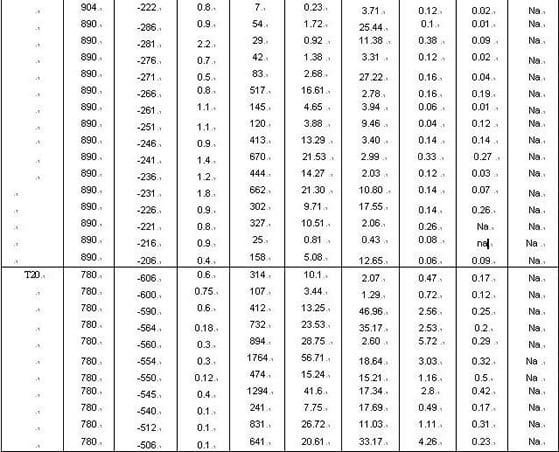

Tunneling assay results are listed in the Table 1 below.

Update on the TLP mine development

A 776m long tunnel, 3.5m by 3.2m in dimension, has been completed to divert water from a narrow valley, thereby providing space for a waste rock dump. To facilitate production by allowing access for large mechanized equipment, the main access tunnel PD730, at 730m elevation, has been widened to 3.5m by 3.2m over 653m in length. A further 180m remains to be completed to enable heavy equipment to reach the T2 and T3 veins.

Table 1. Assay Results

Quality Control

Rock samples were collected by channel sampling the face of the undercut drifts. The channels were usually cut 10cm in width and 5cm in depth producing a sample weighing approximately 2kg to 10kg for each 0.10 to 1.00m interval depending on the thickness of mineralization. Drill cores are NQ/HQ size and drill core samples were taken from sawn half core limited by apparent massive galena sheet contact or shear/alteration contact.

The Company maintains a quality control program to ensure best practice in sampling and analysis of the tunnel samples. The samples are shipped directly in security sealed bags to two labs: the Langfang Institute of Geochemical and Geophysical Exploration (Certification ISO 9001), a well-regarded analytical laboratory in Langfang, Hebei Province near Beijing and analytical Lab of No. 6 Team of Henan Non-Ferrous Metals Geological and Mineral Resources Bureau in Luoyang located 125km by road northeast of the LM Mine.

The sample preparation consists of drying, crushing, and splitting of the sample to 250 grams, and then the sample is pulverized to 200 mesh.

No. 6 Lab utilizes two acid digestion and AA finish on a 0.5 gram sample for lead and zinc. Titration is utilized as a modified process for higher grade materials. Silver is also analyzed using a two acid digestion on a 0.5 gram sample and AA finish.

Langfang Lab uses the ICP-OES process to analyze for lead, zinc and silver a 0.1 gram sample is digested with hot HCL, Hot HNO3, HF and HClO4 (200 degrees centigrade) the pregnant solution is analyzed utilizing mass spectrometry.

Both labs utilize a QA/QC system of duplicates replicates and Standards.

Michael W. Hibbitts, P.Geo, is the Qualified Person on the project under NI 43-101.

About Silvercorp Metals Inc.

Silvercorp Metals Inc. is engaged in the acquisition, exploration, and development of silver related mineral properties focusing in the People’s Republic of China (“China”). In Henan Province it is operating and developing four Silver-Lead-Zinc mines at the Ying Mining Camp, owned through its 77.5% and 70% Chinese subsidiaries. In Guangdong Province, it is applying for a mining permit for the newly acquired GC/SMT property, owned through a 95% Chinese subsidiary. Silvercorp is also exploring the Na-Bao Polymetallic Project in Qinghai Province, China owned through its 82% Chinese subsidiary.

The Company’s common shares are included as a component of the S&P/TSX Composite, the S&P/TSX Global Gold, and the S&P/TSX Global Mining Indexes.

For further information: SILVERCORP METALS INC., Rui Feng, Chairman & CEO, & Lorne Waldman, Corporate Secretary. Phone: (604) 669-9397, Fax: (604) 669-9387, Email: [email protected], Website: www.silvercorp.ca

CAUTIONARY DISCLAIMER — FORWARD LOOKING STATEMENTS

Statements in this press release other than purely historical information, including statements relating to the Company’s future plans and objectives or expected results, constitute forward-looking statements. Forward-looking statements are based on numerous assumptions and are subject to all of the risks and uncertainties inherent in the Company’s business, including risks inherent in mineral exploration, development, and mining. Production and revenue projections are based not on mineral reserves but on mineral resources which do not have demonstrated economic viability. As a result, actual results may vary materially from those described in the forward-looking statements. There can be no assurance that such forward-looking statements will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on such statements. The Company does not undertake to update any forward-looking statements that are incorporated by reference herein, except in accordance with applicable securities laws. The Company expressly disclaims any obligation to update any forward-looking statements. We seek safe harbour.